Caustic soda, or sodium hydroxide (NaOH), is an essential chemical used in various industries

Including the textile, chlor-alkali, and mining sectors. Its concentration and recovery processes are crucial for efficient and sustainable operations. Here, I'll provide an overview of caustic soda concentration and recovery in these industries:

1. Textile Industry:

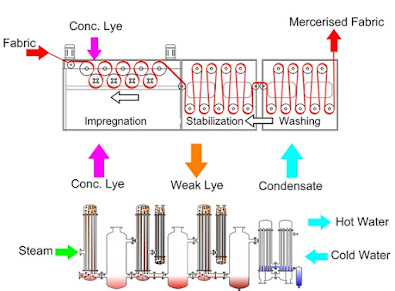

In the textile industry, caustic soda is primarily used for mercerization of cotton and as a reagent in dyeing processes. Concentration and recovery are essential to reduce operating costs and environmental impact.

Caustic Soda Concentration:

Caustic soda is typically supplied in various concentrations (e.g., 25%, 50%, or 73%). Textile manufacturers may need different concentrations for specific applications.

Concentration can be adjusted Caustic Soda Concentration Caustic Soda (Naoh) Recovery in the Textile Chlor Alkali Mining Industry by diluting or concentrating the supplied caustic soda solution as needed.

Precise concentration control is crucial to ensure consistent and high-quality results in textile processing.

Caustic Soda Recovery:

In the textile industry, the recovery of caustic soda is typically not a primary concern. However, measures can be taken to minimize wastage and environmental impact.

Used caustic soda solutions can often be neutralized or treated to reduce their environmental impact before disposal.

2. Chlor-Alkali Industry:

The chlor-alkali industry is a major consumer of caustic soda and chlorine gas, producing both as byproducts of the chlor-alkali process (electrolysis of brine).

Caustic Soda Concentration:

Concentration in the chlor-alkali industry is crucial because the process produces caustic soda as a concentrated solution (usually around 50% concentration) alongside chlorine gas and hydrogen gas.

The concentration can be adjusted through the control of the electrolysis process parameters and separation techniques.

Caustic Soda Recovery:

Caustic soda recovery is a significant concern in the chlor-alkali industry because it is essential to minimize waste and reduce operating costs.

Membrane cell and diaphragm cell technologies are used to separate chlorine and caustic soda, allowing for efficient recovery.

The concentrated caustic soda solution can then be further processed to achieve higher purity if required.

Recovery and reuse of caustic soda are environmentally and economically beneficial.

3. Mining Industry:

In the mining industry, caustic soda is used for various purposes, such as ore leaching and pH control in water treatment.

Caustic Soda Concentration:

Caustic soda concentration in mining applications depends on the specific process requirements, and it may be adjusted as needed.

Dilution or concentration may be carried out onsite to meet the process demands.

Caustic Soda Recovery:

Caustic soda recovery in mining operations is important for cost reduction and environmental compliance.

Various recovery techniques may be employed, including precipitation, ion exchange, and membrane filtration, depending on the specific mining process and water treatment requirements.

Recovered caustic soda can often be reused in subsequent processing steps.

In summary, caustic soda concentration and recovery are important aspects of the textile, chlor-alkali, and mining industries. Each industry has its specific needs and methods for managing caustic soda, depending on the processes involved and environmental considerations. Efficient concentration and recovery processes contribute to cost savings and sustainability in these sectors.

.jpg)

.jpg)

Comments

Post a Comment